Introduction:

Rolling is an industrial process that is considered one of the methods of forming metals. Its idea is to pass the metal cold or hot through heavy cylindrical objects with high hardness (called dolphins) in order to reduce the thickness of the plates or the diameter of the bars.

Course Target:

Discover technical skills and experience related to rolling operations, designing corridors, and related technology.

Contents:

- Continuous casting products and their quality.

- Preheating furnace reheating, its defects and how to avoid it.

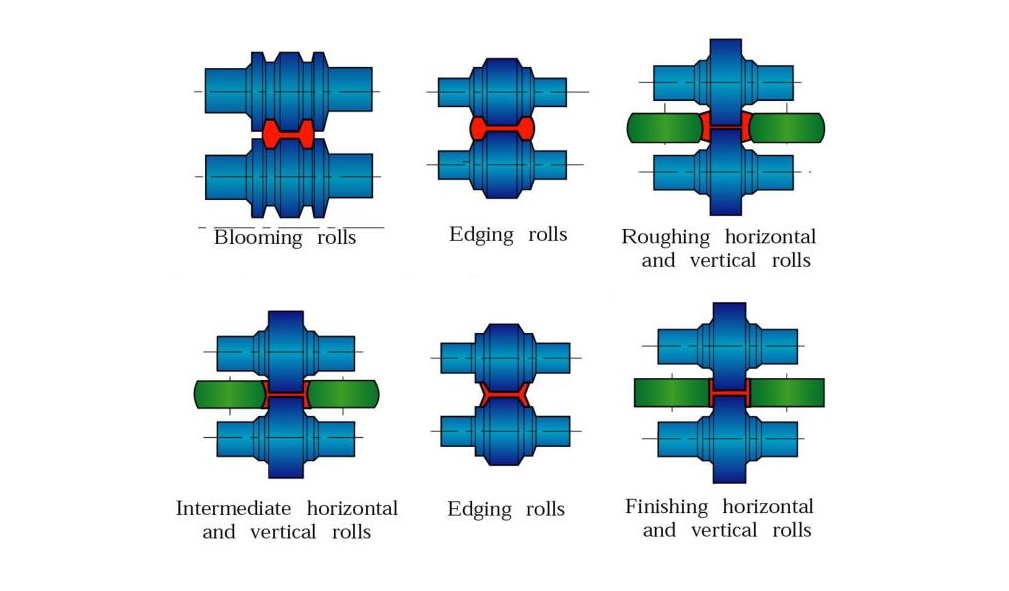

- Forming steel in longitudinal rolling.

- Friction and probability of biting.

- Front crawl, back crawl, and tie area.

- Rolling line and tie line.

- Design presses in longitudinal rolling and rolling line.

- Reducing arcade chains.

- Study the loading area between the rolled block and the pass.

- Mabroum System – Oval.

- Box Archways System.· cracking.

- The final lanes in the rolling squares and the wicker.

- Calculate the amount of area reduction using rolling paths

- Choosing the appropriate rolls for the rolling type, calculating the stresses, and the efficiency of the rolling consumption.

- Defects in roll size and how to correct these defects.

- Calculating loads, moments and capacities on a single shed.

- Cooling and straightening beds, shear and cutting.

- Calculate the rolling efficiency