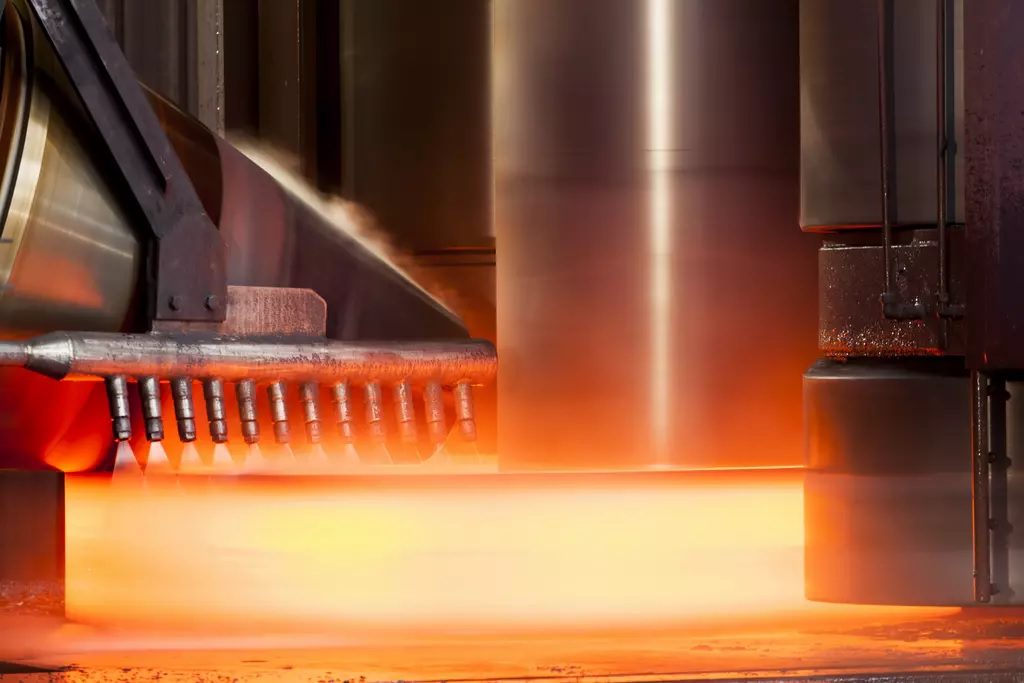

Japanese forging company Ohmi Press Works and Forging has placed an order with SMS group for a RAW 500/400-4500/800 EH radial-axial ring rolling machine.

This ring rolling machine is scheduled to go into operation in May 2024 at OHMI’s Shigaraki plant, providing larger, heavier rings for a wide range of applications in the automotive, shipbuilding, aerospace, mechanical engineering, oil and gas and wind power industries. The new machine will be capable of rolling seamless rings With diameters up to 4500 mm and a maximum height of 800 mm.

OHMI President Hiroyuki Sakamoto said, “We chose the SMS range because we are convinced that it is the best technology in the market and we have been relying on SMS as a system supplier who not only delivers plant and equipment, but also supports us with specialized technical services for many years.”

OHMI benefits from an innovative electro-hydraulic direct drive concept in the RAW EH machine. Depending on the application, energy consumption is reduced by up to 25 to 50 percent compared to traditional ring rolling machines.

This driving concept developed and patented by SMS Group provides more precise and energy efficient control of the ring rolling machine instead of a large central hydraulic system, many small electro-hydraulic motors are used for all the rolling axes, which provide the necessary power on demand.

In contrast to traditional fully hydraulic ring rolling machines, the electro-hydraulic drive concept reduces the need for machine tubes, resulting in significantly lower investment costs.

“OHMI’s confidence in our machines and technology encourages us to reinforce our commitment to fruitful and long-term cooperation and we are confident that our wealth of experience and dedication to developing advanced technologies will help cement OHMI’s position as a leading manufacturer for ring rolling products.

The ring rolling machine ordered by OHMI has a radial rolling force of 5,000 kN and an axial rolling force of 4,000 kN. SMS Group’s supply scope covers all components of the machine including rolling tools, comprehensive software and technology package.

The RAW machine comes with CARWIN control software (computer assisted rolling mill under Windows) and ROLLTECH Rings and ROLLTECH Profiles technology software.

The CARWIN control software checks the target data of the ring to be produced and controls the automatic rolling process together with the CNC system of the ring rolling machine and the ROLLTECH technology package allows the ring rolling process to be simulated and certain process parameters established.

To this end, final loop geometry and materials are brought into the system where the techniques used allow repeatable and reliable turning results to ensure close machining tolerances and contribute to rapid tool changes and remotely controlled tool settings.

The Ring Monitoring System (RMS) can also be used to continuously improve product quality during the rolling process and works in conjunction with the laser line. It provides real-time measurements and is displayed in graphical mode such as ring geometry and shape deviations. State-of-the-art plant technology is approximated by digital solutions developed in SMS-Metrics group and comprehensive overview of production status and device status (SMS-Metrics).